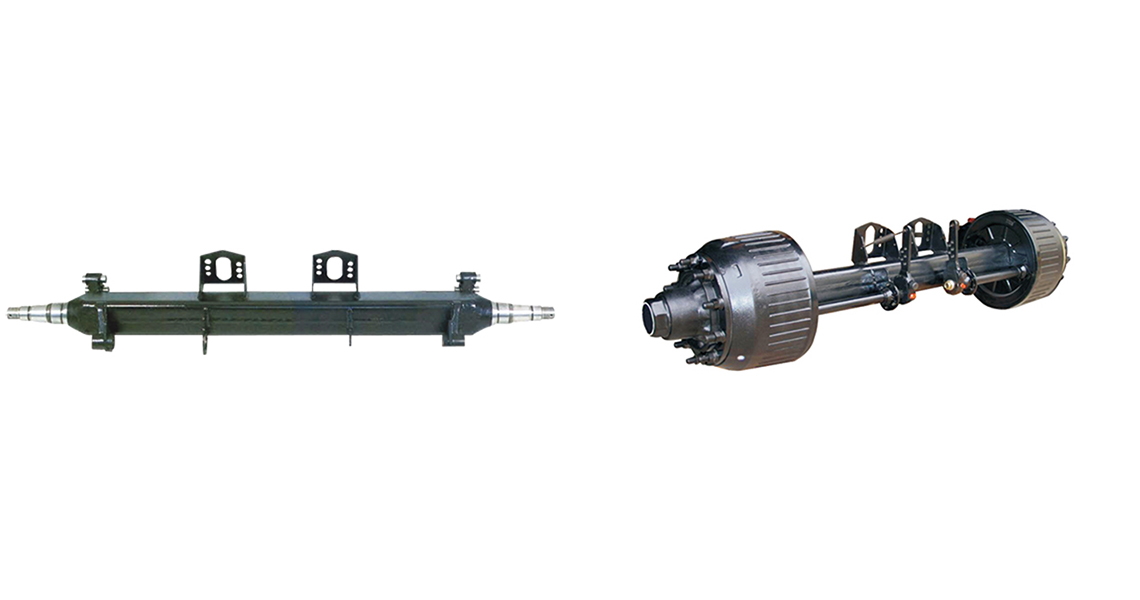

16T Germany Axle

20+ years of experiences (since 2005)

Implementing ISO 9001-2015

Quality testing by an independent laboratory

Warranty: 12 months since shipping date

Fatigue life: 1,700,000 cycles

Bearing position machining precision (Dia.): 0~0.025mm

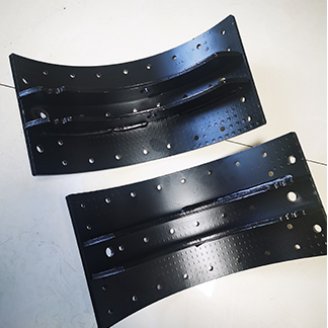

Brake shoe: cylindrical grinding

Both ends of the beam are processed at the same time

The adoption of German semi-trailer axles represents an inevitable choice for modern highway logistics as it evolves toward greater efficiency, safety, precision, and environmental sustainability. These axles transcend the role of mere “running gear” to function as intelligent chassis management systems. While requiring higher initial investment, they deliver significant long-term comprehensive benefits through enhanced cargo protection, operational economy (lightweight design, lift capability), and operational convenience—particularly in high-intensity commercial operations. Consequently, they have become standard equipment for premium logistics fleets.

Product parameters:

Axle Type | Max Capacity | Track | Brake | CentreDistance | Axle Beam(mm) | Centre Distance | Wheel Fixing | Recom | (kg) Axle Weight | Note | |||

Stud | D1P.C.D | D2 Hole Diameter | Total Length | ||||||||||

XH-12 | 12 | 1840 | 420*180 | ≥980 | 150*150 | 420 | 10*M22*1.5 | 335 | 281 | 2156 | 7.5V-20 | ≈372 | Bearing(Inner)33118 |

Bearing(Outer)33213 | |||||||||||||

XH-12 | 12 | 1840 | 420*200 | ≥900 | 150*150 | 354 | 10*M22*1.5 | 335 | 281 | 2156 | 7.5V-20 | ≈396 | Bearing(Inner)33118 |

Bearing(Outer)33213 | |||||||||||||

XH-14 | 14 | 1840 | 420*180 | ≥980 | 150*150 | 420 | 10*M22*1.5 | 335 | 281 | 2188 | 7.5V-20 | ≈402 | Bearing(Inner)33 219 |

Bearing(Outer)33215 | |||||||||||||

XH-14 | 14 | 1840 | 420*200 | ≥980 | 150*150 | 354 | 10*M22*1.5 | 335 | 281 | 2188 | 7.5V-20 | ≈416 | Bearing(Inner)33219 |

Bearing(Outer)33215 | |||||||||||||

XH-14 | 14 | 1840 | 420*220 | ≥980 | 150*150 | 354 | 10*M22*1.5 | 335 | 281 | 2242 | 7.5V-20 | ≈430 | Bearing(Inner)33219 |

Bearing(Outer)33215 | |||||||||||||

XH-16 | 16 | 1850 | 420*220 | ≥900 | 150*150 | 356 | 10*M22*1.5 | 335 | 281 | 2242 | 7.5V-20 | ≈468 | Bearing(Inner)33314 |

Bearing(Outer)32222 | |||||||||||||

XH-16 | 16 | 1850 | 420*220 | ≥980 | 150*150 | 375 | 10*M22*1.5 | 335 | 281 | 2242 | 8.5V-20 | ≈474 | Bearing(Inner)33314 |

Bearing(Outer)3222 | |||||||||||||

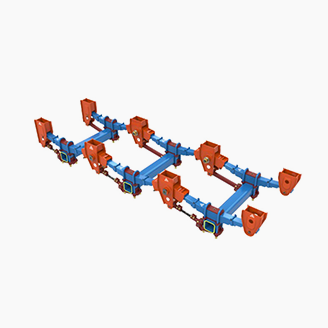

Application:

Premium Trunk Line Trailer Swap Transport: This represents the primary application domain. It has become nearly standard equipment on container chassis trucks and box semi-trailers within high-efficiency logistics fleets, prioritizing delivery timeliness, cargo security, and low operational costs (fuel savings, tire savings).

Precision Instrument and High-Value Goods Transport: Examples include parts logistics for automakers like Mercedes-Benz and BMW, as well as cold chain transportation for electronics, medical devices, and premium food products.

Markets with Stringent Regulations: In regions like Europe and China, where axle load, gross weight, emissions, and safety standards are rigorous, its lightweight and compliance advantages are pronounced.

Intermodal Transport: Frequent connections to ports and rail terminals require platforms that can rapidly adjust height to accommodate different transport vehicles.

Regions with Challenging Road Conditions: Air suspension provides superior protection for vehicles and cargo integrity on rough terrain.